You may be surprised that precast concrete structures from Advance Concrete Products contribute to green building practices in a variety of ways.

Made of all-natural materials, concrete is the most frequently used material on earth, other than water!

The primary ingredients of concrete are mineral based - sand, gravel and cement. When mixed with water, the cement chemically reacts to create a matrix with a high compressive strength. When steel is used for reinforcement, the matrix of our precast concrete envelopes the steel to prevent corrosion. Unlike other construction materials that can rust, rot or otherwise degrade, concrete can actually get stronger if there are unhydrated cement particles available to react with the water.

Precast concrete is manufactured with American made, recycled materials. Several common industrial by-products can be added, which would otherwise go to landfills. Fly ash, slag, and silica fume can be incorporated into the concrete mix as supplementary materials. Reinforcement is made from recycled steel.

Because our precast concrete is 100% factory manufactured, there is little waste created in our plant. Batches are made in precise batching amounts. There is no waste or debris left on a construction site.

The low water-cement ratios possible with precast concrete make it extremely durable, increasing sustainability. In our plant, our highly experienced production team applies strict quality control measures, and is able to achieve consistency in temperature and moisture, which is not possible in field fabricated concrete. Structures manufactured at Advance Concrete are not affected by rain or snow, which can lower the strength of the end product due to increased water content. Our environmentally controlled facility allows us to cast precast concrete products that are strong and long-lasting.

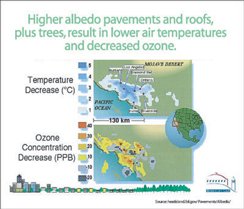

Precast concrete absorbs and releases heat slowly, an attribute that can reduce heating and cooling costs by up to 25%. Temperatures in concrete buildings and structures fluctuate less, allowing for smaller capacity heating, ventilation, and air conditioning systems. Smaller, more efficient HVAC systems create less smog and have less of an impact on climate and air quality.

Precast concrete products including, but not limited to, buildings, tunnels, meter vaults, handholes, and manholes from Advance Concrete can be disassembled. Future additions or modifications can be achieved without wasting the original product. Again, less waste is a result.

Packaging is not normally required to deliver our precast concrete stuctures. Your culvert, storm shelter, bridge section and electrical manholes are secured to a delivery truck using reusable straps.

Many of the precast concrete structures purchased from Advance Concrete Products are incorporated for use in green manufacturing processes. Rain collection tanks, water reclamation/recycling systems for car washes, geothermal systems to naturally heat and cool buildings, and precast concrete conveyer tunnels for recycling aggregate and steel are just a few examples.